CCL Metrology Maintenance

The Business Needs for Maintenance Best Practices

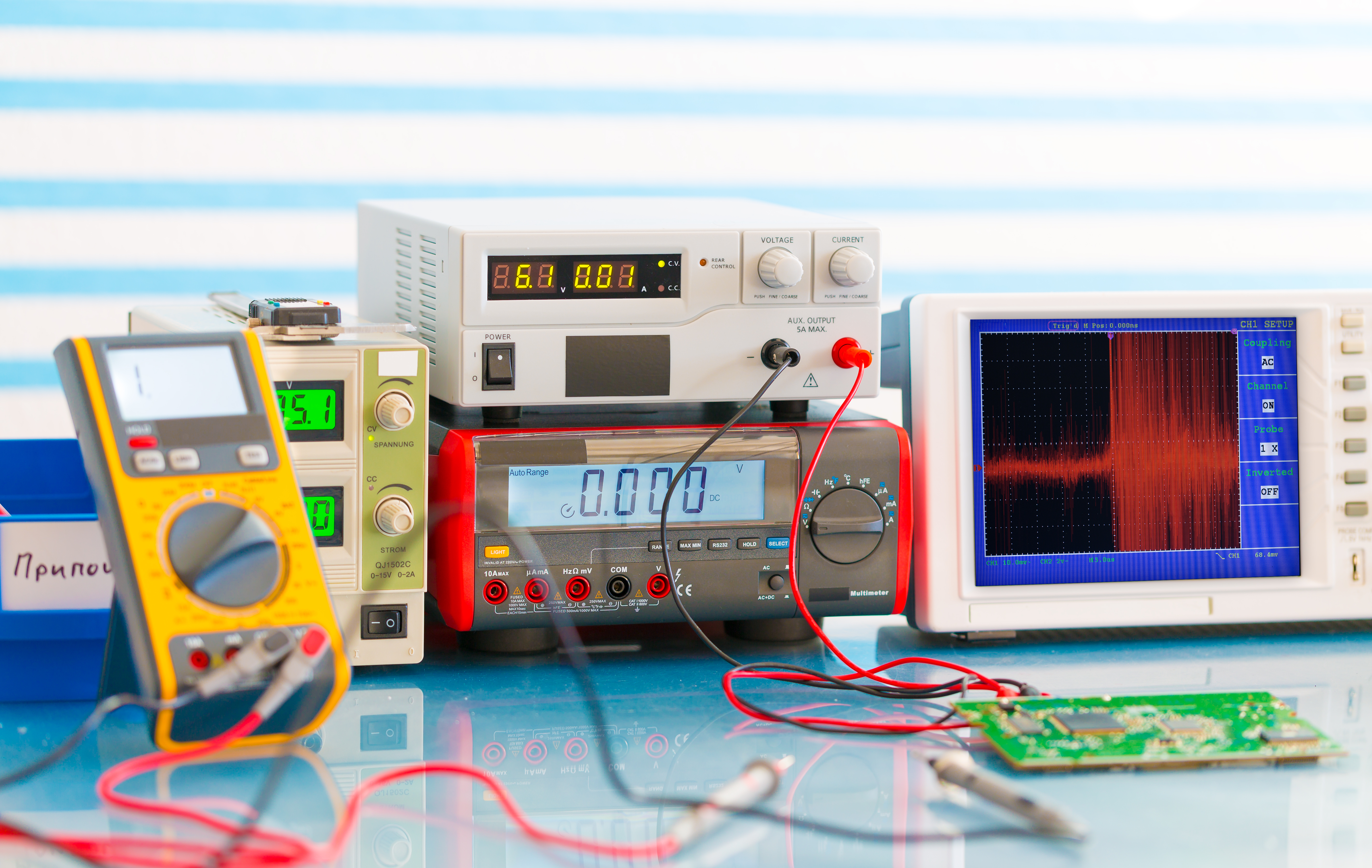

Embrace a Preventive Maintenance Plan

Businesses immensely rely on equipment functionality to provide high quality services. Over time instruments tend to break down causing delays and downtime. Rather than reacting to unplanned failures, establish leading preventative maintenance. This program involves best practices that help reduce unforeseen shutdowns and repairs.

Your Business Needs Maintenance Best Practices to:

- increase uptime

- cut operational costs

- boost equipment performance and lifespan

- eliminate instrument errors and damages

- improve customer satisfaction

- ensure instrument safety and efficiency

Support Your Instrument with Innovative Best Practices

With a shift from reactive to proactive maintenance, your company requires innovative best practices. They involve techniques aimed to manage equipment more effectively and mitigate potential risks of downtime. To embrace maintenance best practices, your business needs a well-organized plan.

Routine instrument inspections will help your company reduce costly equipment failures and improve security.

The Top 7 Maintenance Best Practices Are:

-

analyze instrument compliance specifications

-

create a maintenance strategy

-

develop an ongoing equipment checkup

-

prioritize instrument parts based on importance

-

monitor equipment on a daily basis

-

set up preventive alarms

-

manage maintenance budget

Improve Your Business with Coastal Calibration Laboratories

At CCL, we will handle urgent corrective maintenance and regular preventative maintenance in a timely and high-quality manner.

Our Maintenance Services:

-

verifying instrument reliability

-

applying preventative maintenance to eliminate risks of failure

-

decreasing operation downtime

-

repairing instrument on demand

-

checking instrument validation after maintenance

-

providing transparency and quality reports

-

maintaining regular checkup and update